CNC Part Machining

At Swihart Industries, we specialize in the manufacture of precision CNC machined parts and products. We offer a broad selection of CNC machining services-ranging from boring and broaching to drilling and milling to tapping and turning-to accommodate the part and production needs of customers from a diverse set of industries. By leveraging over 40 years of industry experience and state-of-the-art machining equipment, our team produces high-quality machine components in various designs, sizes, materials, and quantities to tight tolerances.

What Is CNC Part Machining?

CNC machining-i.e., computer numerical control machining-is an umbrella term that encompasses numerous subtractive manufacturing processes (e.g., drilling, milling, and turning), all of which rely on computer software to control the movement and motions of the machine tools. A typical CNC machining operation begins with the development of a 2D or 3D model of the desired part in design software (e.g., CAD). The design is then converted into a format recognizable by the CNC equipment (e.g., STEP or IGES), from which the necessary information-such as the part geometry-is extracted to generate the machine program. The machine program-once loaded into the CNC unit-guides the machine tool as it removes excess material from the workpiece to form the desired part.

Due to the use of computerized technology, the CNC machining process enables parts manufacturers to produce highly precise and accurate pieces. While it accommodates a wide range of part designs, there are several considerations to keep in mind when creating a part design for a specific application. For example, the machining process and the application environment influence which construction material should be employed, while the part size and weight affect the ease to which the part can be machined.

Some of the typical parts produced in machining operations are:

- Brake calipers

- Cylinders

- Industrial food equipment components

- Motor housings

- Pistons

- Power generation/distribution equipment goods

- Pulleys

- Reciprocating and rotary compressors

- Rotors

- Wheel hubs

- Wheels

CNC Part Machining Capabilities at Swihart Industries

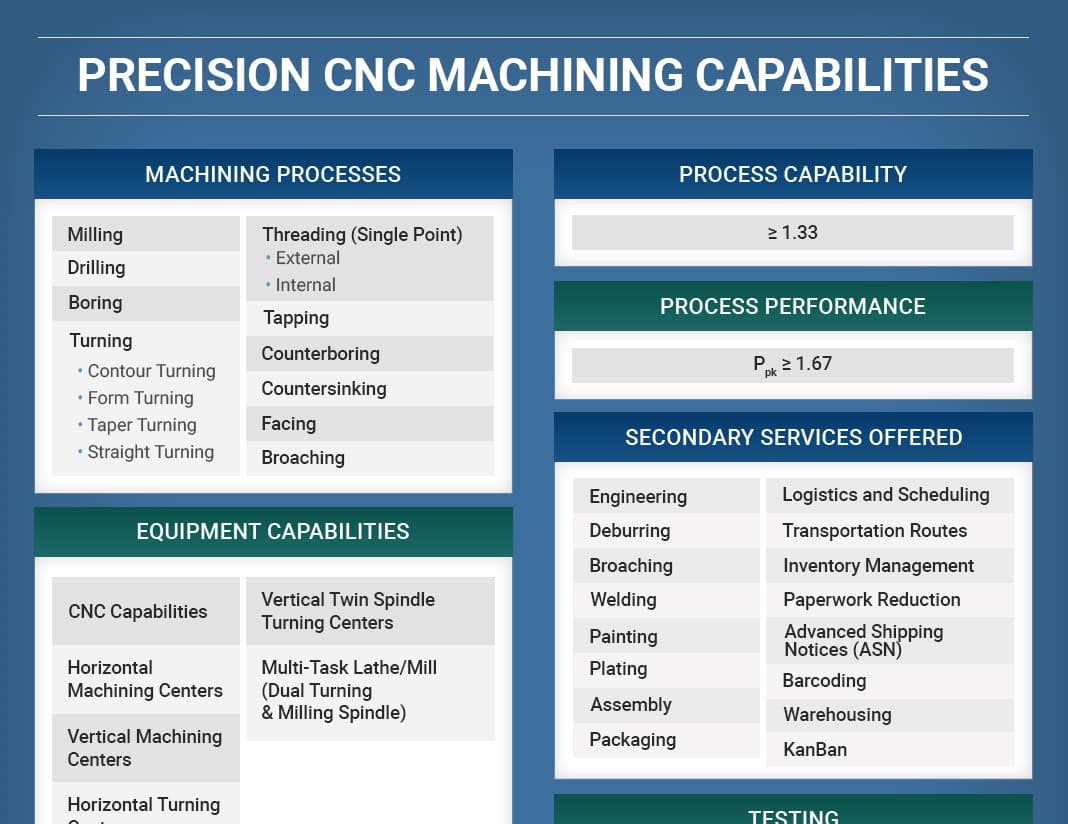

Our ISO 9001:2015 certified facility is equipped with a broad selection of 3-axis, 4-axis, and 5-axis CNC machines, including horizontal and vertical machining centers, horizontal turning centers, vertical twin-spindle turning centers, and multi-task lathes/mills. This equipment enables us to offer the following machining services:

- Boring

- Broaching

- Counterboring

- Countersinking

- Drilling

- Facing

- Milling

- Tapping

- Threading (internal and external)

- Turning

By using the above processes, we fulfill a wide range of machining projects. Our machining capabilities include:

- Construction material: aluminum, brass, copper, iron (cast, ductile, gray), nickel, stainless steel, steel, tin, forged alloy, plastic

- Part weight: up to 2,000 lbs.

- Tolerances: up to ± 0.0002 inches

- Process capability: ≥ 1.33

- Process performance: Ppk ≥ 1.67

- Production volumes: prototype to production

- Lead time: 4–6 weeks for new orders, 1–2 weeks for recurring orders

As an experienced and knowledgeable machining partner, we are committed to ensuring product and process quality in every project. We employ comprehensive testing (dimensional) and inspection (100% layout, 1st piece, and in-process) procedures and advanced quality control technology (CMM, automated tip/probe changer, and calibrated measuring instruments and gages) to ensure each piece we machine fully meets customer specifications and standards. Additionally, we offer several value-added services—including engineering, deburring, painting, plating, assembly, welding, packaging, logistics and scheduling, inventory management, barcoding, and warehousing—to streamline customer production operations.

To find out more about our precision CNC parts machining services or partner with us on your next project, contact us or request a quote today.

Precision CNC Machining Capabilities

| Machining Processes | Milling Drilling Boring Turning

| Threading (Single Point)

Counterboring Countersinking Facing Broaching |

| Equipment Capabilities | CNC Control Capabilities Horizontal Machining Centers Vertical Machining Centers Horizontal Turning Centers | Vertical Twin Spindle Turning Centers Multi-Task Lathe/Mill (Dual Turning & Milling Spindle) |

| Machinery Axis | 3, 4, 5 | |

| Fixturing | In-House Fixturing & Tooling Three-Jaw Chuck Twin Pallets | Automated Spindle Tool Changer Robotic Load / Unload (Pick & Place) |

| Materials Used | Gray Iron Ductile Iron Aluminum Stainless Steel Steel Brass | Cast Iron Forged Alloy Tin Nickel Plastics Copper |

| Turning Diameter | Up to 31.5 in. | |

| Milling Length (X) | Up to 59.8 in. | |

| Milling Width (Y) | Up to 31.5 in. | |

| Milling Height (Z) | Up to 32 in. | |

| Maximum Part Weight | 2,000 lbs. | |

| Tolerance | ± .0002 in. | |

| Process Capability | ≥ 1.33 | |

| Process Performance | Ppk ≥ 1.67 | |

| Secondary Services Offered | Engineering Deburring Broaching Welding Painting Plating Assembly Packaging | Logistics and Scheduling Transportation Routes Inventory Management Paperwork Reduction Advanced Shipping Notices (ASN) Barcoding Warehousing |

| Testing | Dimensional | |

| Inspection | 100% Layout 1st Piece Inspections In-Process Verifications |

|

| Process Manuals | Production Part Approval Process (PPAP) Advanced Product Quality Planning (APQP) Statistical Process Control (SPC) |

|

| Quality Control | Coordinate Measuring Machines (CMM) Automatic Tip / Probe Changer Calibrated Measuring Instruments and Gages |

|

| Production Volume | Prototype to Production | |

| Lead Times Available | 4 to 6 weeks (New) 1-2 weeks (Repeat) |

|

| Delivery | 99.8% On-Time | |

| Supply Chain Management | KanBan Inventory Management / Stocking Program Supplier and Process Management |

|

Additional Information

| Industries Served | Transportation Medium & Heavy Trucking Automotive Commercial Vehicles | Energy Food Processing Equipment Hydraulics Gas Compression |

| Intended Applications | Wheel Hubs Cylinders Rotors Brake Calipers Rotary Compressors Reciprocating Compressors | Power Generation / Distribution Motor Housings Wheels Pulleys Pistons Industrial Food Equipment |

| Industry Standards Met | ISO 9001:2015 Certified TS 16949:2009 Certified |

|

| Software Utilized | SolidWorks Vericut ToolPath MasterCAM QC-Calc (SPC) | CMM Manager OpenDMIS Adobe PDF Images (JPG, GIF, TIFF, BMP) |